Aerospace is truly a global industry with diverse organizational requirements and operational demands. Kestrel Group takes pride in our ability to provide innovative and cost effective solutions using advances in technology is enhanced by our industry experience and the desire to lead by example.

Our customers are our highest priority, their expectations our goal and a company wide process for developing and managing our customer relationships has been, and continues to be, central to our strategy, with clear targets for customer satisfaction.

We embrace challenge by providing a comprehensive range of aircraft certification, management and engineering services worldwide. Among these services are specialized contract consulting, project management, fixed & rotary wing modifications, prototyping and discrete research & development on civil, military and governmental aircraft.

Our people and the trusted relationships we have developed over the many years of working with domestic and foreign governmental authorities who regulate the aerospace industry are the primary key to our success.

Our customers are our highest priority, their expectations our goal and a company wide process for developing and managing our customer relationships has been, and continues to be, central to our strategy, with clear targets for customer satisfaction.

We embrace challenge by providing a comprehensive range of aircraft certification, management and engineering services worldwide. Among these services are specialized contract consulting, project management, fixed & rotary wing modifications, prototyping and discrete research & development on civil, military and governmental aircraft.

Our people and the trusted relationships we have developed over the many years of working with domestic and foreign governmental authorities who regulate the aerospace industry are the primary key to our success.

Certifications

ACE (Aircraft Certification Engineers)

Kestrel Certification Engineers are high level technical inspectors and who have a demonstrated practical background in applied engineering modifications, alterations and repairs. They are experienced in providing field approval services, conformity and regulatory compliance while working closely with Federal Aviation Administration principal inspectors.

Qualifications

Certification engineers are typically graduates of an accredited aviation technical college or university. Most are certificated by the Federal Aviation Administration as an Airframe & Powerplant technicians.Senior certification engineers, in addition to the basic qualifications, typically hold FAA inspection authorization privledges and have more extensive experience with STC’s, field approvals*, conformity and regulatory compliance while working closely with Federal Aviation Administration principal inspectors.

*FAA field approval facilitates approval of systems & equipment installations within their authority, AFMS (aircraft flight manual supplementation) and ICA (instructions for continued airworthiness) and non-complex alterations not requiring development of a supplemental type certificate.

ACE (Aircraft Certification Engineers)

Kestrel Certification Engineers are high level technical inspectors and who have a demonstrated practical background in applied engineering modifications, alterations and repairs. They are experienced in providing field approval services, conformity and regulatory compliance while working closely with Federal Aviation Administration principal inspectors.

Qualifications

Certification engineers are typically graduates of an accredited aviation technical college or university. Most are certificated by the Federal Aviation Administration as an Airframe & Powerplant technicians.Senior certification engineers, in addition to the basic qualifications, typically hold FAA inspection authorization privledges and have more extensive experience with STC’s, field approvals*, conformity and regulatory compliance while working closely with Federal Aviation Administration principal inspectors.

*FAA field approval facilitates approval of systems & equipment installations within their authority, AFMS (aircraft flight manual supplementation) and ICA (instructions for continued airworthiness) and non-complex alterations not requiring development of a supplemental type certificate.

Damage Tolerance/Fatigue

Analysis is accomplished by specially authorized aerospace engineers who use Federal Aviation Administration approved damage tolerance methodologies for pressure vessel penetrations.

Analysis is accomplished by specially authorized aerospace engineers who use Federal Aviation Administration approved damage tolerance methodologies for pressure vessel penetrations.

Aircraft Certification, Engineering, Design & Modifications

Aircraft Importing & Exporting Services

Aerospace Services Worldwide

CONSULTING

Most professionals would agree that effective program management has a critical role in attaining successful results and their involvement should start well before the work begins.

A common paradigm we have found directly associated in many competent organizations would be that program management functions and responsibilities are often considered synonymous with those of project management. Both are quite similar in the preliminary execution phases however; the mixing of macro and micro management functions in critical phases typically evolves into crisis management, delays and loss. In some cases we have found that critical program managerial duties and responsibilities are relegated to someone who has not developed or mastered the skills to properly manage at that level.

We have assembled a team of experienced managers who possess the skills your organization deserves to be successful in aviation and manufacturing. Their practical experience and training is only complimented by their ability to attain positive results which enables them to represent you in a manner consistent with the trust, integrity, service and quality you deserve.

It is said that a laborer works with their hands, a technician with their mind, but a true professional works with their hands, their mind and their heart.

We embrace challenge by providing a comprehensive range of professional consulting services in program management, project management, governmental contracting, discrete research & development, aircraft certification, engineering & manufacturing on fixed and rotary wing aircraft.

A common paradigm we have found directly associated in many competent organizations would be that program management functions and responsibilities are often considered synonymous with those of project management. Both are quite similar in the preliminary execution phases however; the mixing of macro and micro management functions in critical phases typically evolves into crisis management, delays and loss. In some cases we have found that critical program managerial duties and responsibilities are relegated to someone who has not developed or mastered the skills to properly manage at that level.

We have assembled a team of experienced managers who possess the skills your organization deserves to be successful in aviation and manufacturing. Their practical experience and training is only complimented by their ability to attain positive results which enables them to represent you in a manner consistent with the trust, integrity, service and quality you deserve.

It is said that a laborer works with their hands, a technician with their mind, but a true professional works with their hands, their mind and their heart.

We embrace challenge by providing a comprehensive range of professional consulting services in program management, project management, governmental contracting, discrete research & development, aircraft certification, engineering & manufacturing on fixed and rotary wing aircraft.

Engineering , Modifications & Data Approval

FAA DER (Designated Engineering Representatives)

Designated Engineering Representatives are available to support engineering projects involving structures, damage tolerance, electrical, systems & equipment, flammability, flight analyst and flight test.

Designated Engineering Representatives are available to support engineering projects involving structures, damage tolerance, electrical, systems & equipment, flammability, flight analyst and flight test.

FAA DAR (Designated Airworthiness Representatives)

Designated Airworthiness Representatives are available to support export and import of aircraft, parts and products. Issue special flight permits, recurrent airworthiness certificates, provide conformity & compliance inspections and experimental airworthiness certificates.

Designated Airworthiness Representatives are available to support export and import of aircraft, parts and products. Issue special flight permits, recurrent airworthiness certificates, provide conformity & compliance inspections and experimental airworthiness certificates.

Delivery Acceptance

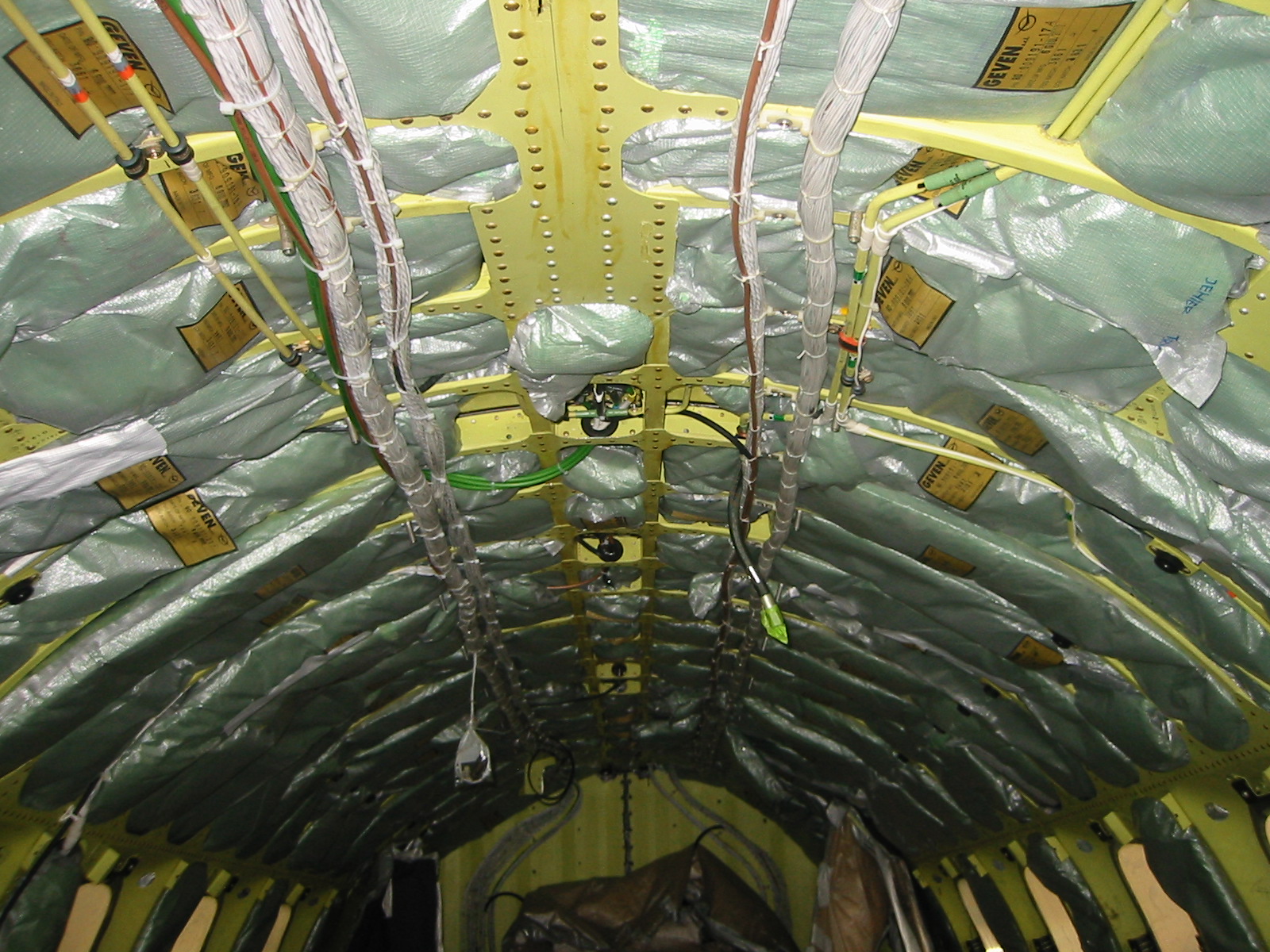

During the interior completion process phase we will monitor the technical aspects of the aircraft including production drawings, airframe, powerplant, system build, quality, serialized component listing, certification documentation, manufacture service bulletin incorporation and product improvements. During final acceptance, a final review of all documents including the AFM, component handbooks, warranty documentation, cabin amenity operational instructions and passenger briefing cards will be conducted. Final review and basic compliance of required placards, systems isolation circuit breaker layouts, switch panels, etc. will be reviewed. Kestrel Group will also conduct a detailed of inspection and inventory of loose and spare equipment. A final report outlining any open items at delivery will be produced, providing a positive means of tracking any remaining issues.

During the interior completion process phase we will monitor the technical aspects of the aircraft including production drawings, airframe, powerplant, system build, quality, serialized component listing, certification documentation, manufacture service bulletin incorporation and product improvements. During final acceptance, a final review of all documents including the AFM, component handbooks, warranty documentation, cabin amenity operational instructions and passenger briefing cards will be conducted. Final review and basic compliance of required placards, systems isolation circuit breaker layouts, switch panels, etc. will be reviewed. Kestrel Group will also conduct a detailed of inspection and inventory of loose and spare equipment. A final report outlining any open items at delivery will be produced, providing a positive means of tracking any remaining issues.

Kestrel Group is ready to conduct a comprehensive pre-buy evaluation as your representative be it during the initial selection phases or prior to your contractual acceptance of a new or pre-owned aircraft.

Our pre-buy evaluation can be custom designed to your specific needs and would typically includesa complete review of the interior and exterior quality standards, specifications, manufacturer service bulletins, airworthiness directives and related method of compliance. In addition a review of the disposition of discrepancies to include life limited components, systems & equipment installations, ground and flight test results. A detailed report will be produced that can be used as a basis for final contract negotiation and future warranty claims.

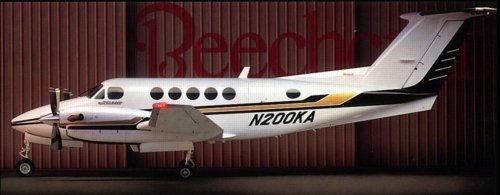

Aircraft Inspection/Evaluation (Green)

Kestrel Group typically performs a comprehensive documentation review and general condition inspection on behalf of you the customer. This preliminary phase of evaluation is critical and necessary to detect discrepancies that may involve serial number listings, major part changes, modification status, and ground test or flight test data.

Technical acceptance of a green aircraft in most cases includes a review of functional test results, identification of deviations between the aircraft as-built with respect to as-was designed, configurations, specifications and documentation control. This final phase would help in the identification of any undocumented damage or related problems that could potentially contribute to future concerns. Depending on these initial findings the customer may be advised to incorporate a more detailed inspection on the airframe, powerplant, systems, components and accessories to identify the actual or physical condition of the product and related discrepancies.

Kestrel Group typically performs a comprehensive documentation review and general condition inspection on behalf of you the customer. This preliminary phase of evaluation is critical and necessary to detect discrepancies that may involve serial number listings, major part changes, modification status, and ground test or flight test data.

Technical acceptance of a green aircraft in most cases includes a review of functional test results, identification of deviations between the aircraft as-built with respect to as-was designed, configurations, specifications and documentation control. This final phase would help in the identification of any undocumented damage or related problems that could potentially contribute to future concerns. Depending on these initial findings the customer may be advised to incorporate a more detailed inspection on the airframe, powerplant, systems, components and accessories to identify the actual or physical condition of the product and related discrepancies.

| Gulfstream G-II | Cessna Citation 5 series | Hawker/Beech 800 series |

| Learjet 31-35 series | Cessna CJ-II series | Hawker/Beech 700 series |

| Piaggio Avanti P-180 | Cessna 150-152-172-195-210 series | Hawker/Beechjet 400 series |

| Pilatus PC-12 | Piper PA-46 series | Hawker/Beech 90, 100 series |

| Shorts C-23 Sherpa | Piper PA-31-41-42 series | Hawker/Beech 200-300 series |

| Cirrus 20/22 | Piper PA-18 series | Hawker/Beech B300-1900 series |

| MBB/Kawasaki BK-117 | ||

| Bell 206 Jet Ranger | Bellanca Super Viking | Hawker/Beech C-12, RC-12 series |

| Bell 204/205 | Boeing PT-17 Stearman | Hawker/Beech C-12J & U-21 series |

| Bell 407 | Grumman OV-1D/RV1-D Mohawk | |

| Bell 430 | ||

| Robinson R-22 Beta | ||

| Fixed & Rotary Wing Aircraft | Normal & Commuter Category Aircraft | Transport Category Aircraft |

Kestrel Group Capabilities

In order to provide some idea of our level of exposure, we have listed a variety of aircraft that Kestrel Group or our qualified associates have participated in with respect to inspection, certification, engineering and modification activities thus-far. As you can see the list represents a wide range of aircraft in both normal and transport categories. Most importantly we want you to understand that our services are not only restricted to those aircraft listed as our services include normal, commuter and transport category aircraft.

Pre-Buy/Condition Evaluation

.jpg)

CUSTOM DESIGN ENGINEERING

AIRCRAFT CERTIFICATIONS

PROGRAM MANAGEMENT

Program & Project Management

KESTREL GROUP 15 COACHWHIP COURT SIMPSONVILLE, SOUTH CAROLINA - 29680 USA TEL: 864-918-2416 FAX: 864-228-1908

© 2007-2008 ALL RIGHTS RESERVED

Clear Vision Beyond The Horizon

Kestrel

Group

Group